3M

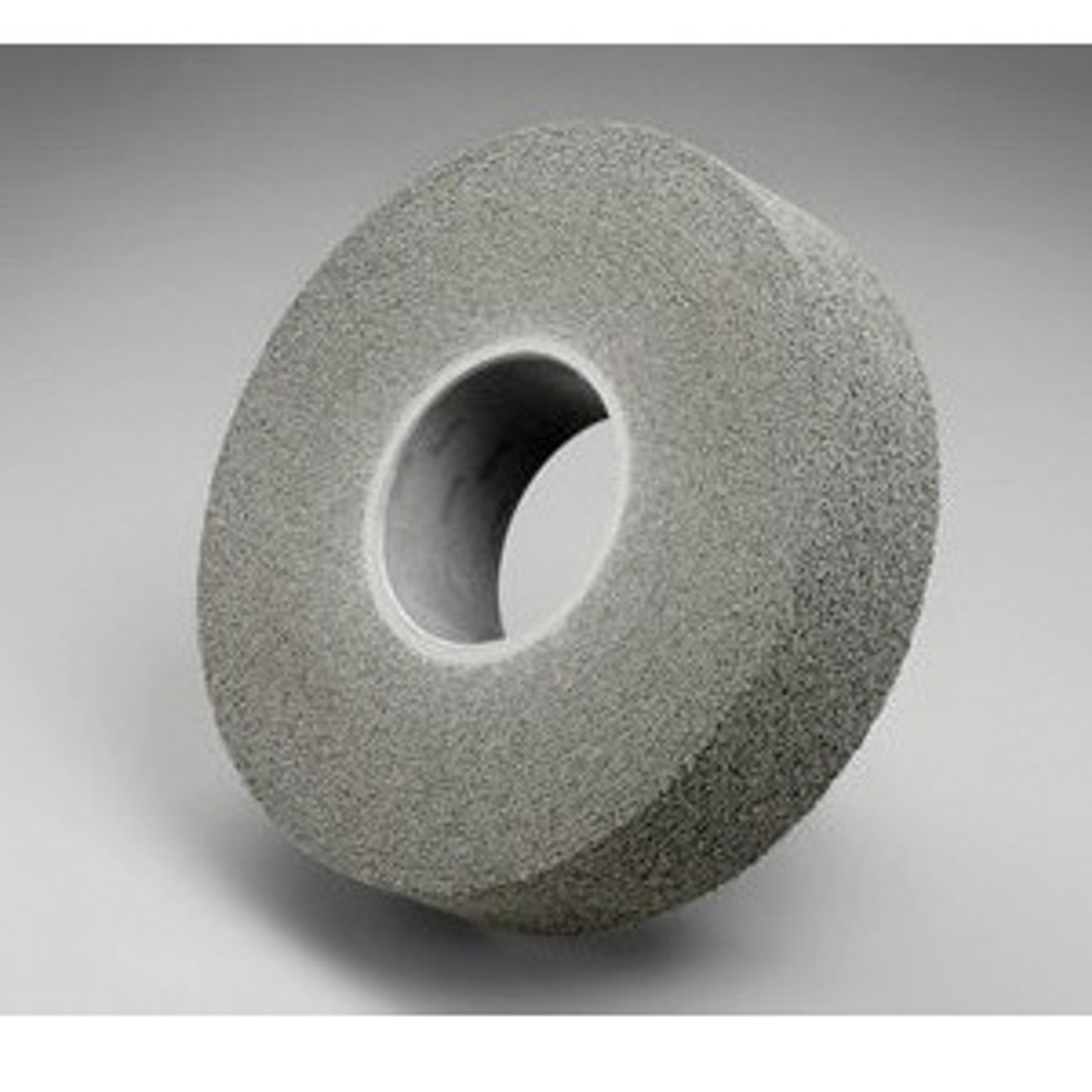

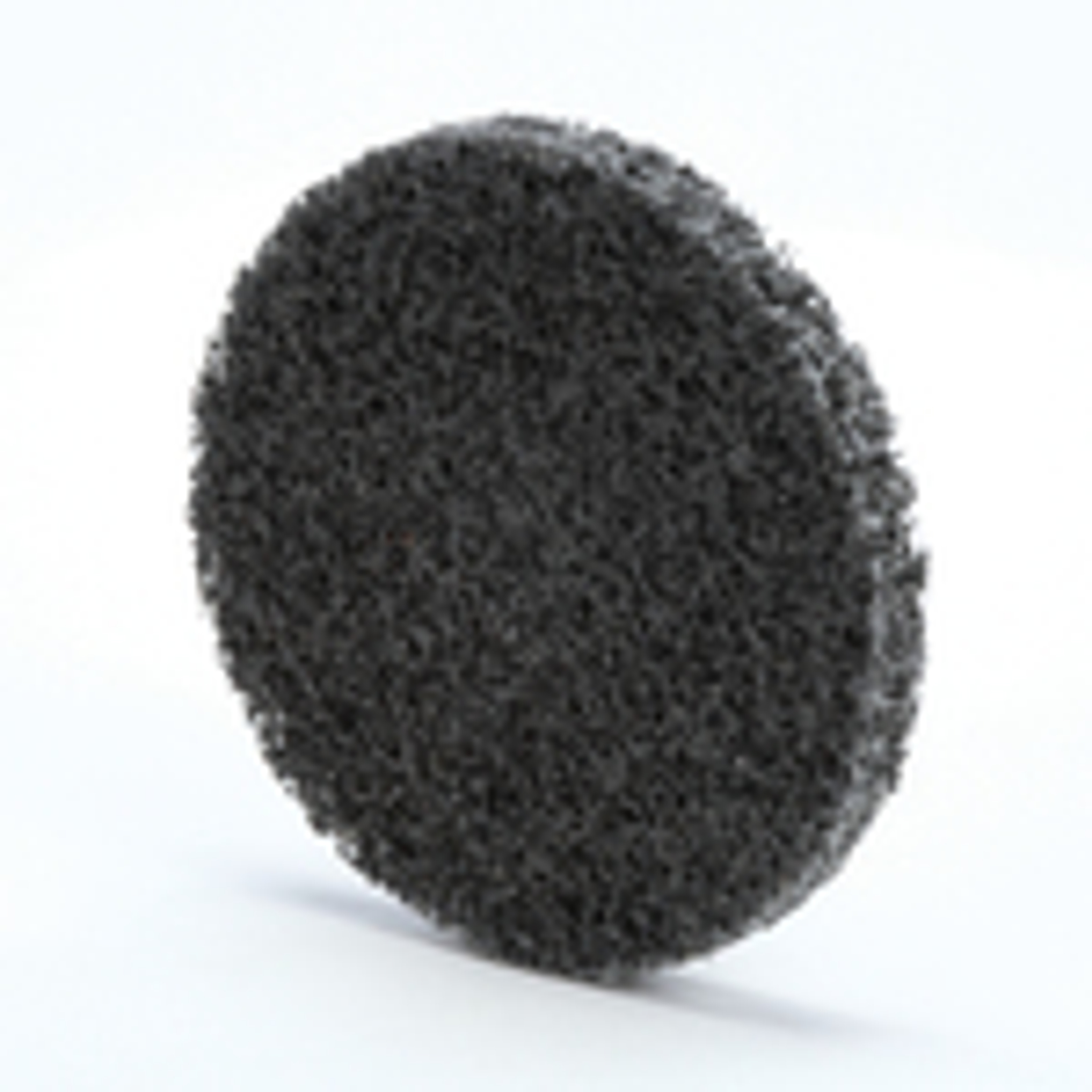

Scotch-Brite 7100180149 XL-UB Type EXL Unitized Block, 12 in OAL x 12 in OAW, 1/8 in THK Overall, Aluminum Oxide Abrasive

Need a quote on a big project? Click Here

Scotch-Brite, 7100180149, Unitized Block, Type EXL, Series: XL-UB, 12 in Overall Width, 12 in Overall Length, Aluminum Oxide Abrasive, 1/8 in Overall Thickness, Medium Grade, Applicable Materials: Ferrous Alloys, Metal and Wood

Scotch-Brite EXL unitized block is a strong, durable high performance block built for a wide range of deburring and finishing applications. One of the best benefits of a unitized block is that it can be converted into another form shape it into mounted points, use it by hand or bond it to tools for honing. Tailored to fit picking mineral, grade and density Scotch-Brite EXL unitized block comes in a few variations, making it easy for operators to find an abrasive tailored to their application. Unitized densities, for example, range from 2 to 8. Likely, a density of 2 is a good choice when trying to keep part geometry intact. Flexible and soft, low density abrasives tend to conform better to the workpiece. Conversely, if a workpiece requires a stiffer, harder abrasive, a density of 8 may be a better choice. Priorities shift depending on the workpiece and application and the unitized block comes in multiple densities to suit various requirements. In addition to densities, operators can choose from different grades of aluminum oxide and silicon carbide. Aluminum oxide is a synthetic mineral known for its high cut-rate, hardness, strength and low heat retention. It is suitable on a wide variety of substrates in both woodworking and metalworking, including ferrous alloys. Silicon carbide is used for creating different aesthetic finishes. It tends to wear faster than aluminum oxide but leave brighter finishes. Built for strength Scotch-Brite EXL unitized block does offer uniform benefits, including durability and consistency. Unitized products are produced by compressing and curing multiple layers of abrasive material together. The tough and layered unitized construction gives the abrasive more durability, helping it resist wear and stand up to tough areas like edges and contours. The many benefits of Scotch-Brite abrasives Altogether, non-woven technology makes Scotch-Brite industrial abrasives unique. A combination of fiber strands, resin and abrasive mineral forms a thick, open web. The spring like nature of the fibers responds to contours and effectively removes unwanted burrs, soils and contaminants while maintaining the geometry of the workpiece, which in turn reduces rework and boosts productivity. Gaps in the web allow swarf to escape, so debris does not clog the mineral. Fibers in the web continually breakdown with use to reveal fresh mineral for consistency, sharp cut and long service life. From aesthetic finishing to weld blending, deburring and more, Scotch-Brite abrasives work fast and deliver consistent results, part after part.

Additional information

Related products

Reviews 0

No reviews have been added for this product.