Runner Cutters

Runner cutters are essential tools for industrial workers involved in plastic injection and tool and die processes. Designed to mill and create precise channels in molds, these high-quality tools enhance performance and efficiency on the job. With durable construction and precision engineering, runner cutters streamline your workflow, ensuring clean cuts and reducing downtime. Whether you're shaping intricate designs or maintaining consistent quality, these tools are built to meet the demands of your work environment, making your tasks easier and more efficient.

Choosing the Right Runner Cutters for Your Needs

When it comes to selecting runner cutters for creating channels in molds, especially for plastic injection and tool and die processes, it's crucial to understand the specific requirements of your project. Runner cutters are essential tools that ensure precision and efficiency in mold-making, impacting the quality and performance of the final product. This guide will help you navigate the key factors to consider when purchasing runner cutters, ensuring you make an informed decision that meets your operational needs.

- Material Compatibility: Ensure the runner cutter is compatible with the materials you are working with, such as different types of plastics or metals.

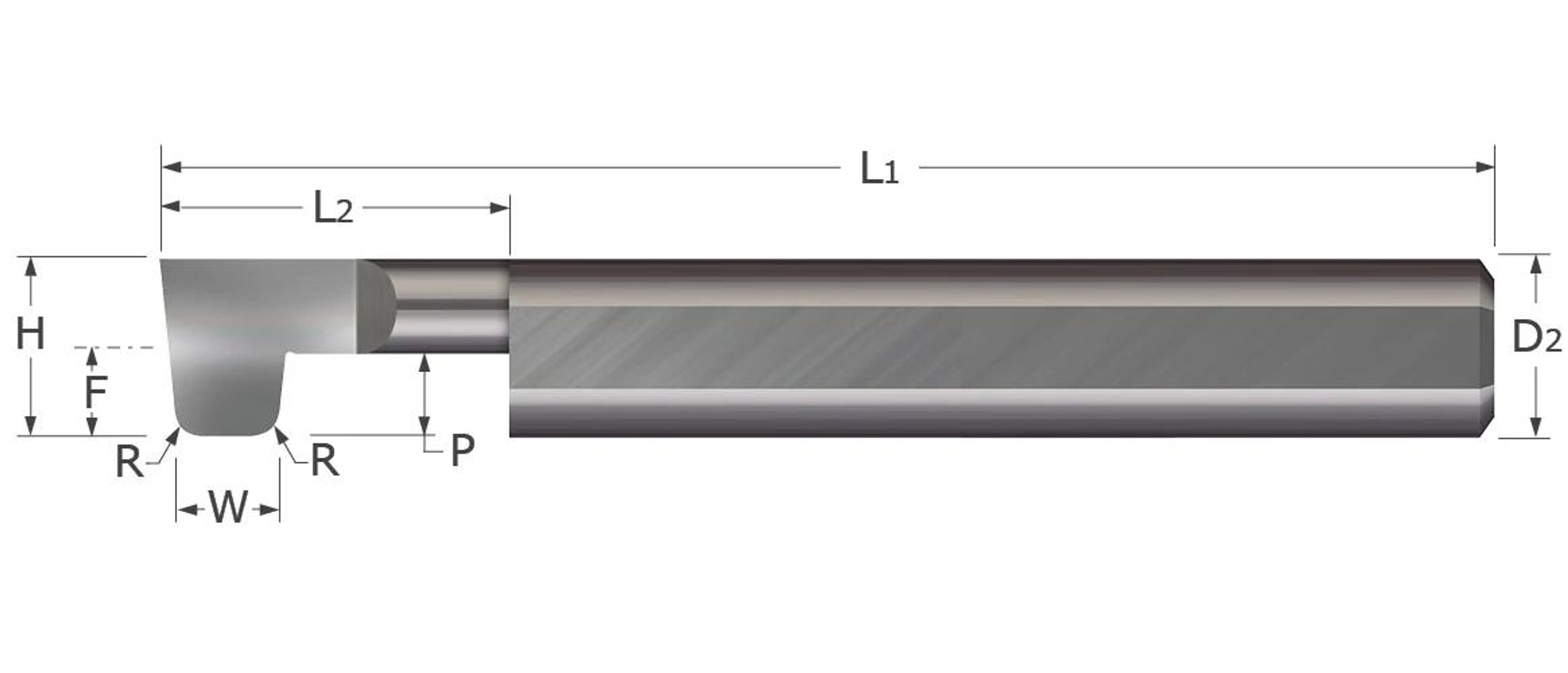

- Size and Dimensions: Choose the appropriate size and dimensions of the cutter to match the specifications of your mold design.

- Durability and Quality: Look for high-quality materials and construction to ensure longevity and consistent performance.

- Precision and Accuracy: Opt for cutters that offer high precision to maintain the integrity of your mold channels.

- Ease of Use: Consider the ease of installation and operation, especially if you need to switch between different cutter sizes frequently.

- Cost-Effectiveness: Balance the initial cost with the long-term benefits and savings from reduced maintenance and replacement needs.

- Brand Reputation: Research brands known for reliability and customer satisfaction in the industry.

By taking these factors into account, you can select runner cutters that not only fit your current project requirements but also enhance your overall production efficiency. Investing in the right tools is crucial for maintaining high standards in mold-making and ensuring the success of your plastic injection and tool and die processes.

Ready to find the perfect runner cutters for your needs? Browse our selection and take the first step towards optimizing your mold-making operations today!