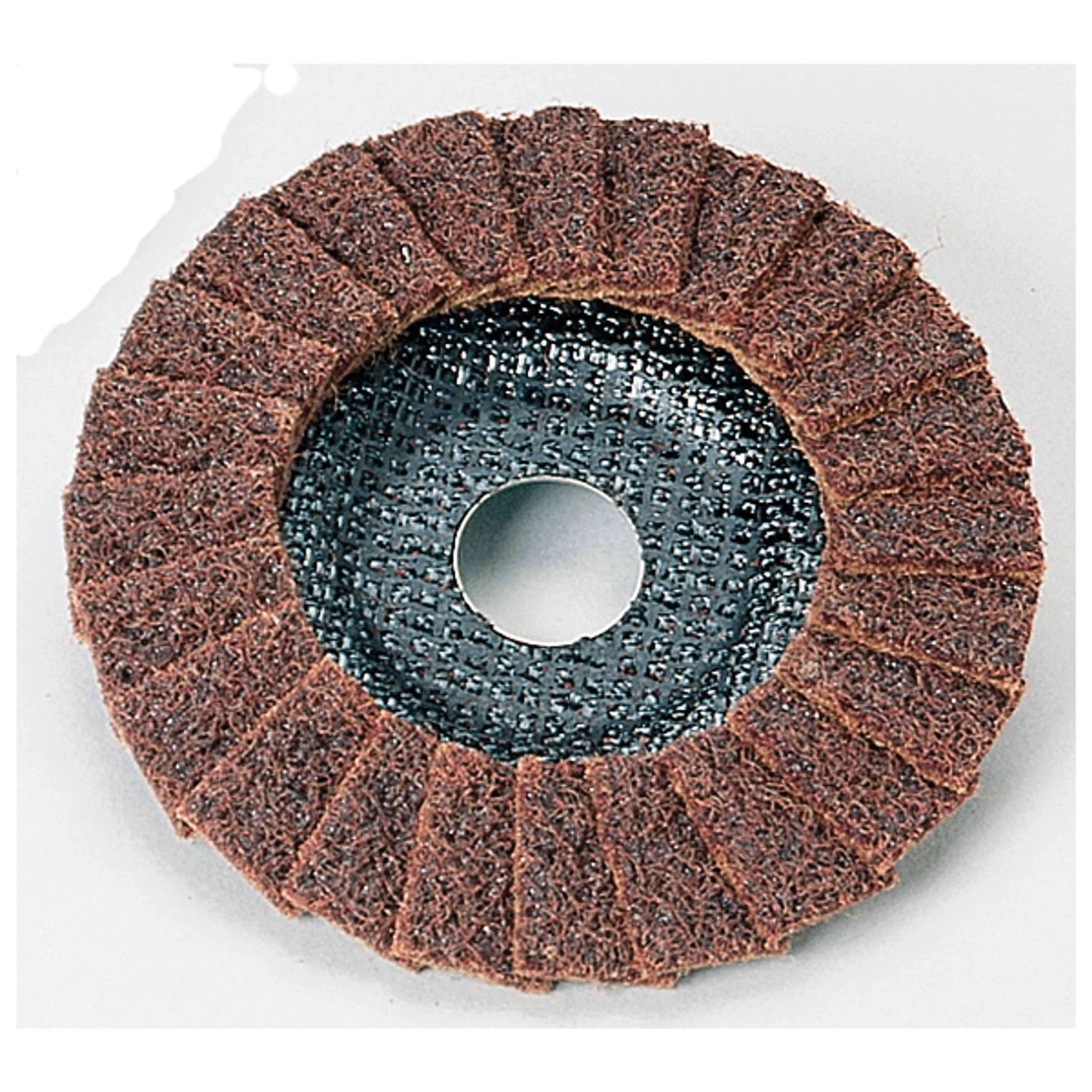

Non-Woven Flap Discs

Non-Woven Flap Discs are essential for industrial workers who need reliable tools for fabricating, deburring, cleaning, polishing, and finishing tasks. These discs consist of multiple abrasive sheets attached to a core, designed to wear away during use, continually exposing fresh abrasive surfaces for a consistent finish. Their unique design ensures each grit flap contacts the workpiece at varying angles, minimizing scratches and adapting to complex shapes and tight contours. Ideal for enhancing performance and efficiency, these discs make demanding jobs easier and more precise.

Understanding Non-Woven Flap Discs for Your Fabrication Needs

Non-woven flap discs are essential tools for various fabrication, deburring, cleaning, polishing, and finishing tasks. These discs are composed of multiple abrasive sheets attached to a core, designed to wear away during use, which continuously exposes a fresh abrasive coating. This feature ensures an even finish and prevents scratches, as each grit flap contacts the workpiece at a slightly different angle. Ideal for finishing complex shapes and tight contours, non-woven flap discs conform to the shape of the surface material, making them indispensable for intricate jobs.

When selecting the right non-woven flap disc for your needs, it's crucial to consider several factors to ensure optimal performance and results. Below is a list of key factors to guide your purchasing decision:

- Grit Size: Choose the appropriate grit size based on the level of abrasiveness required for your task. Coarser grits are suitable for heavy material removal, while finer grits are ideal for finishing and polishing.

- Disc Diameter: Select a disc diameter that matches your tool and the size of the workpiece for efficient coverage and performance.

- Material Compatibility: Ensure the flap disc is compatible with the material you are working on, whether it's metal, wood, or composites.

- Backing Material: Consider the backing material of the disc, as it affects durability and flexibility. Common options include fiberglass, plastic, and metal.

- Speed Rating: Check the maximum RPM rating of the flap disc to ensure it matches your tool's speed capabilities for safe operation.

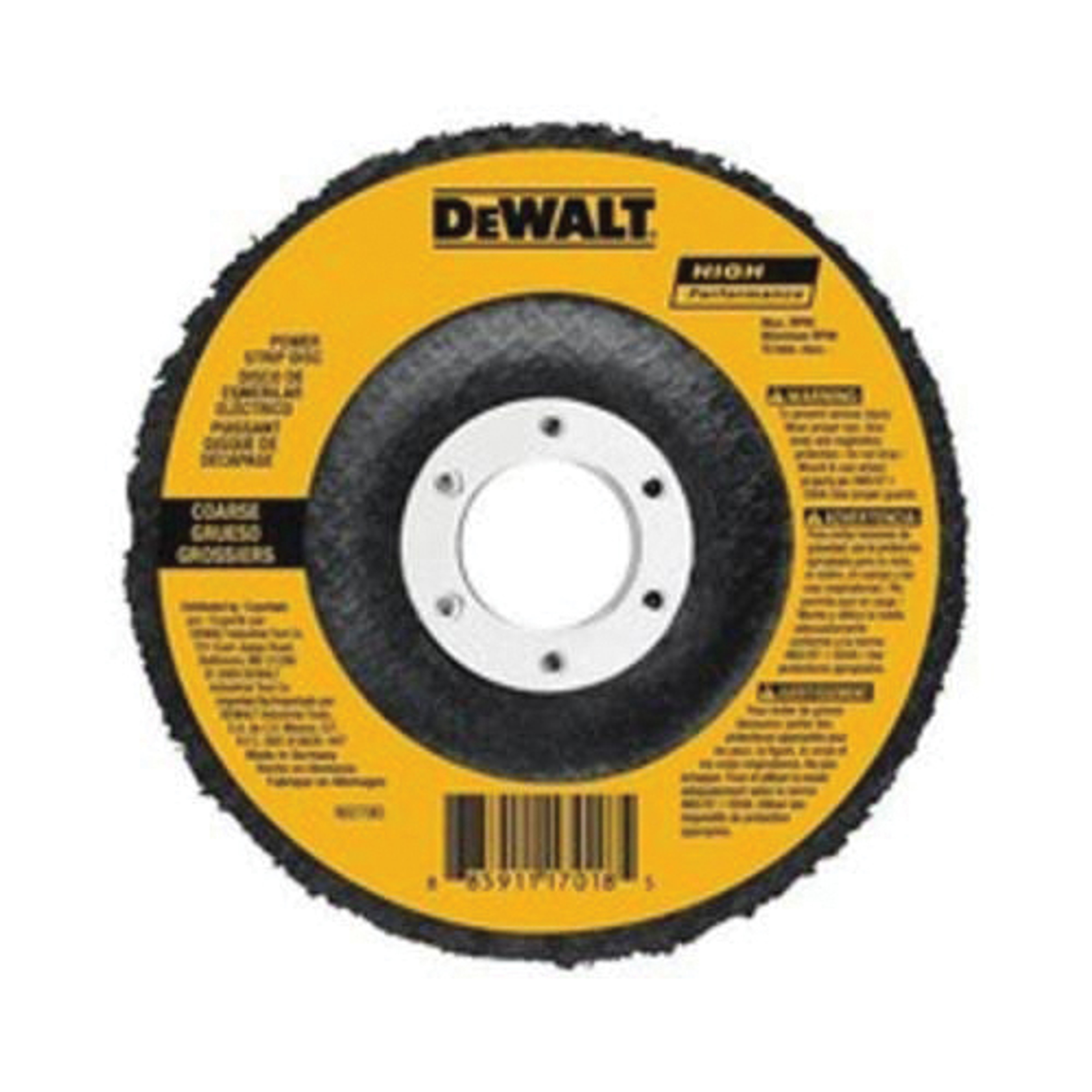

- Brand and Quality: Opt for reputable brands known for quality and reliability to ensure consistent performance and longevity.

By taking these factors into account, you can select the most suitable non-woven flap disc for your specific application, ensuring efficient and high-quality results. Whether you're working on a complex shape or a tight contour, the right flap disc will make all the difference in achieving a professional finish.

Ready to enhance your fabrication projects with the perfect non-woven flap disc? Browse our selection now and find the ideal disc for your needs. Experience the difference in quality and performance today!