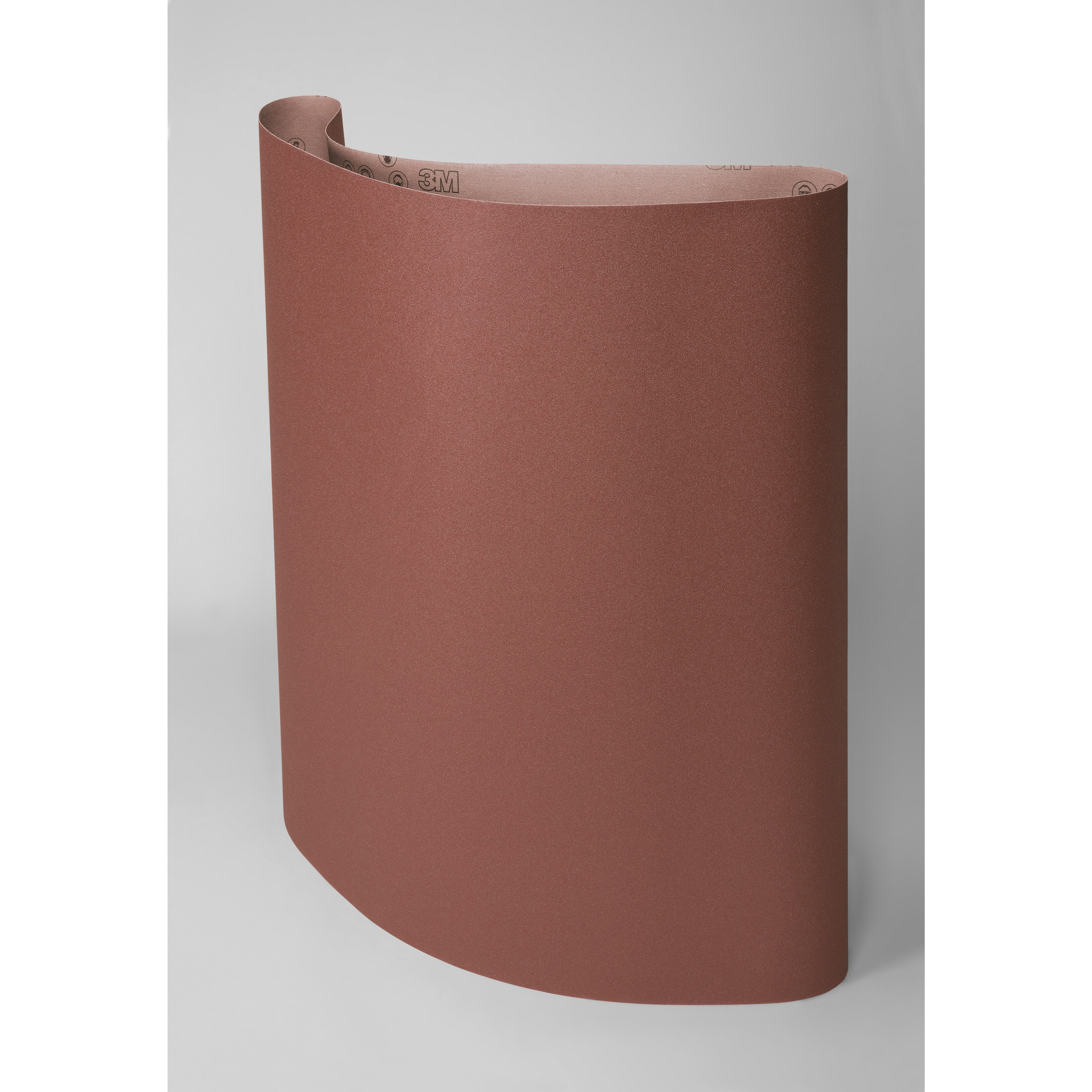

Coated Abrasives

Coated abrasives are essential tools for industrial workers seeking to enhance performance and efficiency. These abrasives consist of abrasive grains bonded to flexible substrates like paper, cloth, or plastic films, offering a range of grit sizes from very coarse to ultrafine. Whether you're smoothing surfaces, removing material, or preparing for finishing, coated abrasives provide the precision and durability needed to tackle tough jobs with ease. By choosing the right grit and substrate, you can achieve optimal results, reduce downtime, and make your workday more productive.

Understanding Coated Abrasives: Your Guide to Making the Right Purchase

Coated abrasives are essential tools in various industries, providing the perfect solution for smoothing, polishing, and finishing surfaces. These abrasives consist of abrasive grains bonded to a flexible substrate, such as paper, cloth, vulcanized fiber, or plastic films. They are available in a wide range of grit sizes, from very coarse to ultrafine, catering to different applications and surface requirements. Whether you're a professional craftsman or a DIY enthusiast, understanding the key factors in selecting the right coated abrasive can significantly impact the quality of your work.

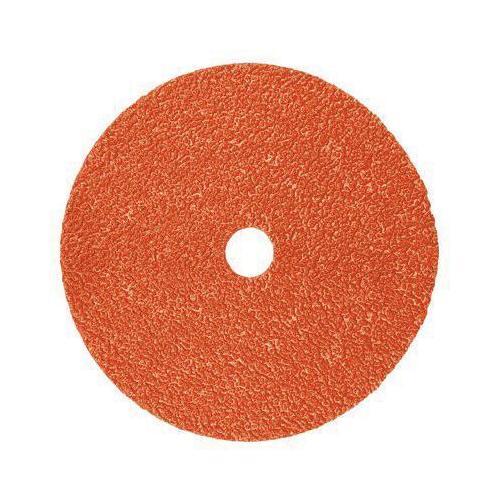

- Grit Size: Choose the appropriate grit size based on the level of abrasiveness required. Coarse grits are ideal for heavy material removal, while finer grits are suitable for finishing and polishing.

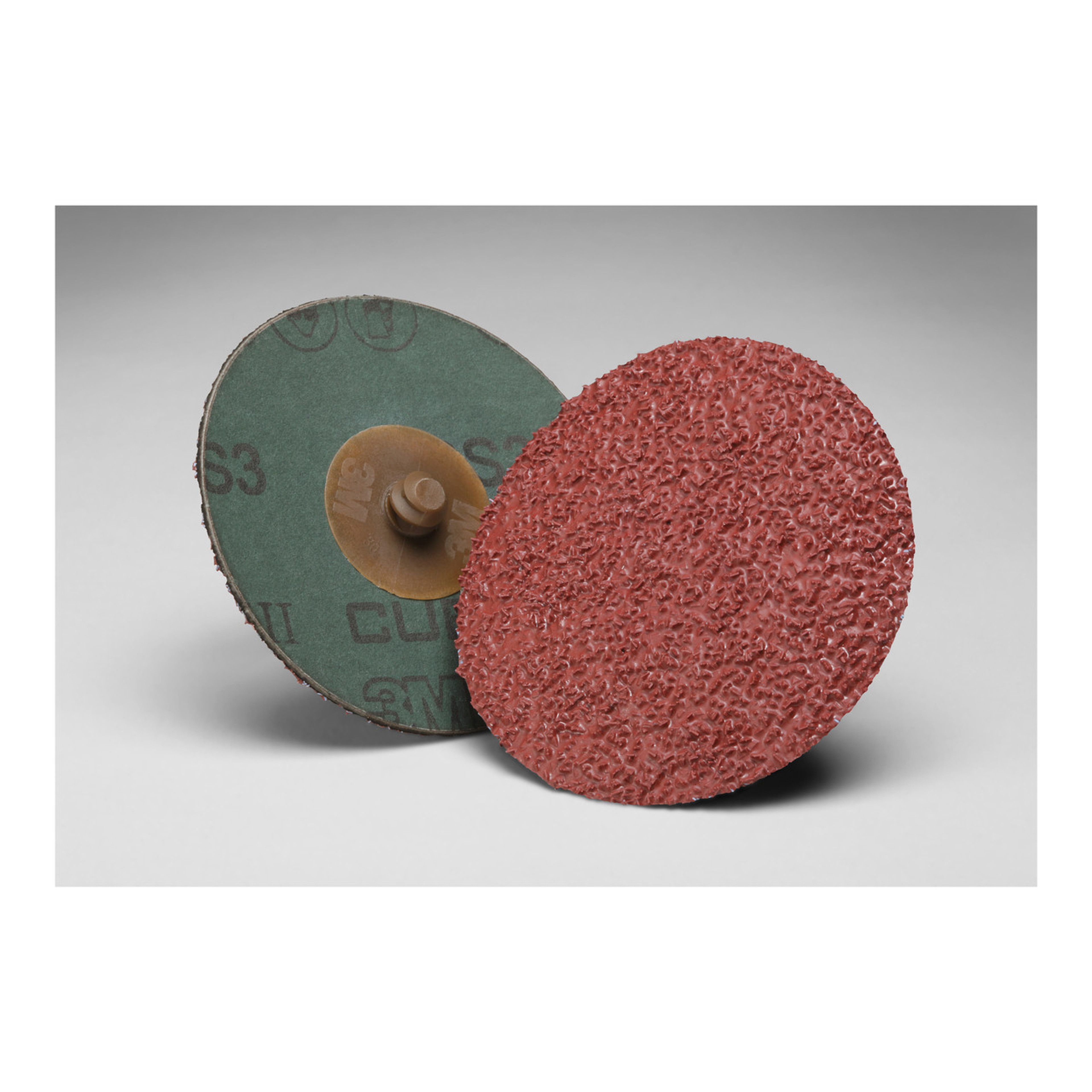

- Substrate Material: Consider the substrate material for flexibility and durability. Paper is suitable for lightweight applications, while cloth and vulcanized fiber offer more strength and flexibility.

- Type of Abrasive Grain: Different grains, such as aluminum oxide, silicon carbide, and zirconia alumina, offer varying levels of hardness and cutting efficiency. Select the grain type based on the material you are working with.

- Backing Weight: The backing weight affects the strength and flexibility of the abrasive. Heavier backings provide more durability, while lighter backings offer greater flexibility.

- Coating Density: Open coat abrasives are less likely to clog and are suitable for softer materials, while closed coat abrasives provide a more aggressive cut for harder surfaces.

By considering these factors, you can ensure that you select the right coated abrasive for your specific needs, enhancing the efficiency and quality of your work. Whether you're sanding wood, metal, or composites, the right abrasive can make all the difference in achieving a smooth, professional finish.

Ready to find the perfect coated abrasive for your project? Explore our extensive range of high-quality abrasives and make your purchase today. Shop Now and experience the difference in performance and results!